- Ball Valves

- Flanged Floating Ball Valve

- Trunnion Mounted Ball Valves

- Threaded Ball Valves

- Welded End Ball Valves

- Gate Valves

- Flanged Gate Valves

- Welded Gate Valves

- Threaded Gate Valves

- Globe Valves

- Flanged Globe Valves

- Weld End Globe Valves

- Threaded Globe Valves

- Check Valves

- Flanged Check Valves

- Welded Ends Check Valves

- Threaded Check Valves

- Y Type Strainers

- Flanged Y Type Strainers

- Threaded Y Type Strainers

- Forged Steel Valves

- Flanged Forged Steel Valves

- Flanged Forged Steel Gate Valve

- Flanged Forged Steel Pressure Seal Gate Valve

- Flanged Forged Steel Globe Valve

- Flanged Forged Steel Pressure Seal Globe Valve

- Flanged Forged Steel Check Valve

- Flanged Forged Steel Pressure Seal Check Valve

- Flanged Forged Steel Y Type Strainer

- Threaded Forged Steel Valves

- Welded Ends Forged Steel Valves

Flanged Forged Steel Pressure Seal Gate Valve

Introduction

Forged steel flanged pressure seal gate valve is the most common on-off valve. This pressure seal valve is mainly composed of valve body, disc, bonnet, valve gland, gasket, bolt and nut. Disc is the on-off component. It utilizes disc to connect (by fully opened) or cut off (by fully closed) the medium in the pipeline. The disc moves up and down in the direction perpendicular to the moving medium. Gate valve cuts off the medium movement like a sluice gate, so it’s also called sluice valve.

Application

Flanged pressure seal gate valve can be widely applied as fluid regulating and intercepting equipment in various pipelines, such as tap water, sewage, construction, petroleum, chemical, food, medicine, textile, electric power, shipbuilding, metallurgy, and energy pipeline systems.

Classification

Flanged pressure seal valves can be classified according to fluid’s pressure grades (such as 900LB, 1500LB and 2500LB).

Advantages

1. Flanged pressure seal gate valve is suitable for using in pipelines on various transmission systems.

2. The great sealing property and high wear resistance of the valve contributes to reducing the cost.

3. 18 months warranty and lifelong technology service are available for our products.

4. Valve seat is replaceable, which makes maintenance more simple and convenient.

5. Valve body adopts precision casting technique.

6. Twice shot blasting processing on outer surface makes the flanged steel valve look fine and smooth.

7. Numerical control processing is utilized on valve disc.

8. Forged steel flanged pressure seal gate valve needs small torsion to open.

Pressure: CLASS900-2500 PN16.0-42.0

1. Welded Bonnet/Pressure Sealed Bonnet

2. Reduced Port

3. Solid Wedge Gate

4. Flange Ends/Butt-Welding Ends

Technical Specification of Flanged Pressure Seal Gate Valve

| Technical Specification | ASME/API/BS | GB/JB |

| Design Standard | ASME B16.34/BS5352 | GB/T12235 GB/T12224 |

| Pressure-Temperature Rating | ASME B16.34 | GB/T12224 |

| Face-Face | ASME B16.10 | GB/T12221 JB/T96-95 |

| Flange Ends | ASME B16.5 | GB/T9113JB/T82.1~82.4 |

| Butt Welding Ends | ASME B16.25 | GB/T12224 |

| Inspection & Test | API598 | JB/T9092 |

Material List for Main Parts of Flanged Pressure Seal Gate Valve

| No. | Part Name | ASTM | |||

| Carbon Steel | Tailess Steel | Alloy Steel | |||

| 1 | Body | A105 | LF2/LF3 | A182 F304 | A182 F11/F22 |

| 2 | Disc | A182F6a | A182F6a | A182 F304 | A182 F6a |

| 3 | Stem | A276-410 | A276-410 | A276-304 | A276-410 |

| 4 | Gasket | Graphite + 304 | |||

| 5 | Sealing Ring | Graphite | |||

| 6 | Yoke | A216-WCB | A216-WCB | A351 CF8 | A216-WCB |

| 7 | Bonnet | A105 | LF2/LF3 | A182 F304 | A182 F11/F22 |

| 8 | Gland | A216-WCB | A216-WCB | A351 CF8 | A216-WCB |

| 9 | Bolt | A193 B7 | A320L7 | A193 B8 | A193 B16 |

| 10 | Packing | Graphite | |||

| 11 | Stem Bushing | A276-410 | A276-410 | A276-304 | A276-410 |

| 12 | Gland | A216-WCB | A216-WCB | A351 CF8 | A216-WCB |

| 13 | Eye Blot | A193 B7 | A320 L7 | A193 B8 | A193 B7 |

| 14 | Stem Nut | A276-410 | |||

| 15 | Hand Wheel | A197 or A47-32510 | |||

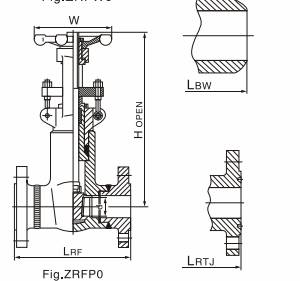

Main Dimensions & Weight of Flanged Pressure Seal Gate Valve

| Pressure | Size | Main Dimension of Valve | Weight(kg) | ||||||||||

| mm | in. | d | LRF | LBW | LRTJ | H | W | ||||||

| WB | PB | WB | PB | ||||||||||

| CLASS900 PN16.0 | 15 | 1/2 | 10 | 216 | 216 | 216 | 197 | 321 | 180 | 9.8 | 11.5 | ||

| 20 | 3/4 | 13 | 229 | 229 | 229 | 211 | 321 | 180 | 9.7 | 11.2 | |||

| 25 | 1 | 19 | 254 | 254 | 254 | 238 | 321 | 180 | 9.5 | 10.8 | |||

| 32 | 1-1/4 | 24 | 279 | 279 | 279 | 257 | 380 | 200 | 17.5 | 18 | |||

| 40 | 1-1/2 | 40 | 305 | 305 | 305 | 276 | 414 | 200 | 21.6 | 22 | |||

| 50 | 2 | 50 | 368 | 368 | 371 | 320 | 502 | 300 | 42.7 | 44 | |||

| CLASS1500 PN26.0 | 15 | 1/2 | 10 | 216 | 216 | 216 | 197 | 321 | 180 | 9.8 | 11.5 | ||

| 20 | 3/4 | 13 | 229 | 229 | 229 | 211 | 321 | 180 | 9.7 | 11.2 | |||

| 25 | 1 | 19 | 254 | 254 | 254 | 238 | 321 | 180 | 9.5 | 10.8 | |||

| 32 | 1-1/4 | 24 | 279 | 279 | 279 | 257 | 380 | 200 | 17.5 | 18 | |||

| 40 | 1-1/2 | 40 | 305 | 305 | 305 | 276 | 414 | 200 | 21.6 | 22 | |||

| 50 | 2 | 50 | 368 | 368 | 371 | 320 | 502 | 300 | 42.7 | 44 | |||

| CLASS2500 PN42.0 | 15 | 1/2 | 10 | 264 | 264 | 264 | 197 | 321 | 180 | 12.3 | 13 | ||

| 20 | 3/4 | 13 | 273 | 273 | 273 | 211 | 321 | 180 | 12.1 | 12.7 | |||

| 25 | 1 | 19 | 308 | 308 | 308 | 238 | 321 | 180 | 11.8 | 12.5 | |||

| 32 | 1-1/4 | 24 | 349 | 349 | 352.2 | 257 | 380 | 200 | 20.9 | 21.8 | |||

| 40 | 1-1/2 | 40 | 384 | 384 | 387.2 | 276 | 414 | 200 | 27.5 | 29.3 | |||

| 50 | 2 | 50 | 451 | 451 | 454.2 | 320 | 502 | 300 | 53.3 | 55.4 | |||

Attentions When Selecting Flanged Pressure Seal Gate Valves

1. Medium (Pressure Seal Valve’s Material and Corrosivity)

2. Working Pressure (Intensity and Airtightness)

3. Working Temperature

4. Size of Diameter

5. Valve Form (Category, Structure and Connection Type)

Attentions When Using Flanged Pressure Seal Gate Valves

Please avoid small opening of the disc, since the washout of medium in high speed flow will accelerate sealing surface’s damage.

Payment, Package, Delivery and Maintenance

1. Products can be paid by T/T, D/P, D/A, L/C or according to your requirement.

2. Pressure seal valves are packaged by standard exported wooden cases.

3. Our flanged pressure seal gate valves are transported by sea, railway or air.

4. Guarantee period of our products is 18 months. Lifelong technology service is offered.

TallKee Valve Industry specializes in researching, designing, manufacturing and selling pressure seal valves. Our main products include ball valves, gate valves, globe valves, check valves, strainers and forged steel valves. Our flanged pressure seal gate valves are exported to Brazil, Argentina, Mexico, Canada, Russia, Kazakhstan, Indonesia, South Korea, Japan, Australia, Bulgaria, Spain, France, England, Sweden, Dubai, Arab, Pakistan, South Africa, etc.

- Flange Forged Steel Globe ValveGlobe valve (also called stop valve) is mainly composed of valve body, disc, shaft pin and stem. Flanged forged steel globe valve is a valve with closure member (disc) moving along with the center line with valve seat. Since it has relative short opening and closing stroke, this valve is very suitable for cutting off and regulating medium flow. Our flanged...