- Ball Valves

- Flanged Floating Ball Valve

- API 2PC Flanged Floating Ball Valve

- API 3PC Flanged Floating Ball Valve

- API 3 Way Flanged Floating Ball Valve

- API Flanged Ball Valve with ISO5211 Mounting Pad

- API Wafer Type Ball Valve

- API Wafer Type Ball Valve with ISO5211 Mounting Pad

- API 6D Floating Ball Valve

- DIN 2PC Flanged Floating Ball Valve

- DIN 3PC Flanged Floating Ball Valve

- DIN 3 Way Flanged Floating Ball Valve

- DIN Wafer Type Ball Valve

- DIN Wafer Type Ball Valve with ISO5211 Mounting Pad

- Trunnion Mounted Ball Valves

- Threaded Ball Valves

- Welded End Ball Valves

- Gate Valves

- Flanged Gate Valves

- Welded Gate Valves

- Threaded Gate Valves

- Globe Valves

- Flanged Globe Valves

- Weld End Globe Valves

- Threaded Globe Valves

- Check Valves

- Flanged Check Valves

- Welded Ends Check Valves

- Threaded Check Valves

- Y Type Strainers

- Flanged Y Type Strainers

- Threaded Y Type Strainers

- Forged Steel Valves

- Flanged Forged Steel Valves

- Threaded Forged Steel Valves

- Welded Ends Forged Steel Valves

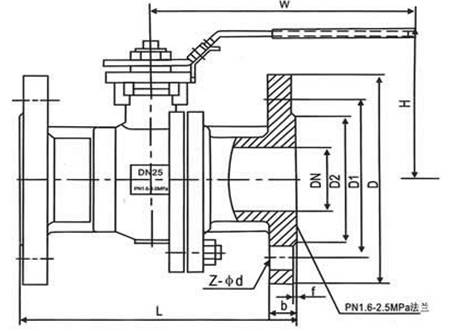

API Flanged Ball Valve with ISO5211 Mounting Pad

Description

API flanged ball valve with ISO 5211 mounting pad is used for cutting off, distributing and changing the flowing direction of medium. This API ball valve characterizes small volume, reliable sealing performance, simple structure, convenient maintenance and high corrosion resistance. It is widely used in water, oil, natural gas, weak corrosive liquid, etc.

Advantages

1. Our flanged ball valves are guaranteed within the first 18 months.

2. KERUI pays much importance on technology renovation, process improvement, structure optimization and quality improvement on API ball valves.

3. We have excellent after-sale service system, providing timely and optimal service, thus winning widespread recognition and praise of our customers.

Performance

1. PTEE has been adopted for our flanged ball valves, leading excellent performance and superior sealing property.

2. The sealing performance and wear resistance of API ball valves are guaranteed, ensuring a longer service life.

Components of API Flanged Ball Valve with ISO 5211 Mounting Pad

| Name | Material | ||||

| Valve Body | CF8M | CF8 | WCB | Ti | |

| Bonnet | CF8M | CF8 | WCB | Ti | |

| Ball | 316 | 304 | Ti | ||

| Valve Seat | PTFE, PPL | ||||

| Nut | A193-B8 | A193-B7 | A193-B8 | ||

| Valve Stem | 316 | 304 | Ti | ||

| Thrust Washer | PTFE, Flexible Graphite | ||||

| Packing | PTFE, Flexible Graphite | ||||

| Gasket | Reinforced PTFE and Flexible Graphite | ||||

| Packing Press Ring | 304 | ||||

| Belleville Spring | 301 | ||||

| Nut | 304 | ||||

| Locking Device | 304 | ||||

| Handle (1/2’’-3’’) | 304 | ||||

| Handle Cover (1/2’’-3’’) | Plastics | ||||

| Locating Pin(1/2’’-3’’) | 304 | ||||

| Seal Gasket | PTFE, Flexible Graphite + Stainless Steel Wire | ||||

| Steel Pipe(4’’-6’’) | Galvanized | ||||

| Spanner | CF8 | ||||

| Positioning Screw | 304 | ||||

Technical Parameters of API Flanged Ball Valve with ISO 5211 Mounting Pad

| Nominal Pressure | Nominal Diameter | d | L | D | D1 | D2 | b | f | z-Φd | H | W |

| Class 150 | 1/2″ | 13 | 108 | 89 | 60.5 | 35 | 11.5 | 1.6 | 4-16 | 79 | 135 |

| 3/4″ | 19 | 117 | 98 | 70 | 43 | 11.5 | 1.6 | 4-16 | 84 | 135 | |

| 1″ | 25 | 127 | 108 | 79.5 | 51 | 12 | 1.6 | 4-16 | 95 | 170 | |

| 1-1/4″ | 32 | 140 | 117 | 89 | 64 | 13 | 1.6 | 4-16 | 103 | 170 | |

| 1-1/2″ | 38 | 165 | 127 | 98.5 | 73 | 15 | 1.6 | 4-16 | 111 | 200 | |

| 2″ | 51 | 178 | 152 | 120.5 | 92 | 16 | 1.6 | 4-19 | 120 | 200 | |

| 2-1/2″ | 64 | 190 | 178 | 139.5 | 105 | 18 | 1.6 | 4-19 | 153 | 300 | |

| 3″ | 76 | 203 | 190 | 152.5 | 127 | 19 | 1.6 | 4-19 | 163 | 300 | |

| 4″ | 102 | 229 | 229 | 190.5 | 157 | 24 | 1.6 | 4-19 | 182 | 400 | |

| 5″ | 127 | 356 | 254 | 216 | 186 | 24 | 1.6 | 8-22 | 260 | 500 | |

| 6″ | 152 | 394 | 279 | 241.5 | 216 | 26 | 1.6 | 8-22 | 280 | 800 | |

| 8″ | 203 | 457 | 343 | 298.5 | 270 | 29 | 1.6 | 8-22 | - | 1100 | |

| Class 300 | 1/2″ | 13 | 140 | 95 | 66.5 | 35 | 15 | 1.6 | 4-16 | 79 | 135 |

| 3/4″ | 19 | 152 | 117 | 82.5 | 43 | 16 | 1.6 | 4-19 | 84 | 135 | |

| 1″ | 25 | 165 | 124 | 89 | 51 | 18 | 1.6 | 4-19 | 95 | 170 | |

| 1-1/4″ | 32 | 178 | 133 | 98.5 | 64 | 19 | 1.6 | 4-19 | 103 | 170 | |

| 1-1/2″ | 38 | 190 | 156 | 114.5 | 73 | 21 | 1.6 | 4-22 | 111 | 200 | |

| 2″ | 51 | 216 | 165 | 127 | 92 | 23 | 1.6 | 4-22 | 120 | 200 | |

| 2-1/2″ | 64 | 241 | 190 | 149 | 105 | 26 | 1.6 | 8-19 | 153 | 300 | |

| 3″ | 76 | 283 | 210 | 168.5 | 127 | 29 | 1.6 | 8-22 | 163 | 300 | |

| 4″ | 102 | 305 | 254 | 200 | 157 | 32 | 1.6 | 8-22 | 182 | 400 | |

| 5″ | 127 | 381 | 279 | 235 | 186 | 35 | 1.6 | 8-22 | 260 | 500 | |

| 6″ | 152 | 403 | 318 | 270 | 216 | 37 | 1.6 | 12-22 | 280 | 800 | |

| 8″ | 203 | 502 | 381 | 330 | 270 | 42 | 1.6 | 12-25 | - | 1100 |

- API Wafer Type Ball ValveAPI wafer type ball valve is mainly used for cutting off, distributing and altering the flowing direction of medium. Characterizing in small volume, reliable sealing performance, simple structure, convenient maintenance and high corrosion resistance, this API valve can be widely used in such pipelines as water, oil, natural gas, weak corrosive liquid...