Home » Products » Check Valves » Flanged Check Valves » API Cast Steel Single Plate Wafer Check Valve

Product List

- Ball Valves

- Flanged Floating Ball Valve

- Trunnion Mounted Ball Valves

- Threaded Ball Valves

- Welded End Ball Valves

- Gate Valves

- Flanged Gate Valves

- Welded Gate Valves

- Threaded Gate Valves

- Globe Valves

- Flanged Globe Valves

- Weld End Globe Valves

- Threaded Globe Valves

- Check Valves

- Flanged Check Valves

- Flanged Cast Steel Swing Type Check Valve

- Flanged Stainless Steel Swing Type Check Valve

- API Cast Steel Dual Plate Wafer Check Valve

- API Stainless Steel Dual Plate Wafer Check Valve

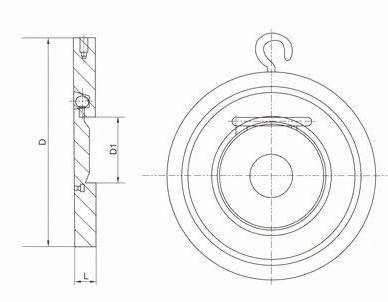

- API Cast Steel Single Plate Wafer Check Valve

- API Stainless Steel Single Plate Wafer Check Valve

- DIN Cast Steel Swing Type Check Valve

- DIN Cast Steel Lift Type Check Valve

- DIN Cast Steel Dual Plate Wafer Type Check Valve

- DIN Cast Steel Single Plate Wafer Type Check Valve

- DIN Cast Steel Lift Wafer Type Check Valve

- DIN Stainless Steel Swing Type Check Valve

- DIN Stainless Steel Lift Type Check Valve

- DIN Stainless Steel Dual Plate Wafer Type Check Valve

- DIN Stainless Steel Single Plate Wafer Type Check Valve

- DIN Stainless Steel Lift Wafer Type Check Valve

- Welded Ends Check Valves

- Threaded Check Valves

- Y Type Strainers

- Flanged Y Type Strainers

- Threaded Y Type Strainers

- Forged Steel Valves

- Flanged Forged Steel Valves

- Threaded Forged Steel Valves

- Welded Ends Forged Steel Valves