DIN Lift Type Welded Check Valve

Introduction

Our butt welded check valves have passed DIN certification. DIN lift welded check valve, also known as non return valve, is installed on one-way flow pipelines. It is mainly made up of valve body, disc, bonnet and gasket. This type of lift check valve is used to prevent reverse flow and leakage of medium, such as fluid, gas, etc. It is also applied to stop reversal of pump and driving motor. Lift type check valves can be widely applied in tap water, sewage, construction, petroleum, chemical, food, medicine, textile, electric power, shipbuilding, metallurgy, and other pipeline systems.

Advantages of Butt Welded Check Valve

1. DIN lift welded check valve features small closing torsion and excellent sealing performance.

2. CNC processing technology is adopted to produce disc.

3. Disc is with high strength and stiffness.

4. Disc restrainer is designed to prevent that the open position of disc is too high to be shut down.

5. High intensity and flexibility of rocker are beneficial to close disc.

6. Flow channel in DIN lift welded check valve is unobstructed and fluid resistance is small.

7. Disc closes fast because the travel journey of disc is small.

8. Water hammer pressure and impact force for closing valve are small.

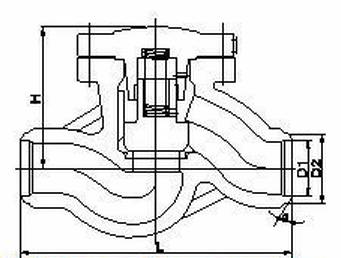

Structure Map of Butt Welded Check Valve

Working Process

DIN lift type butt welded check valve opens and closes automatically depending on force from media flowing. Lift check valve allows medium to flow through it in only one direction, and prevents reverse direction flow. Disc will open under the pressure of forward flow fluid. When fluid flows in reverse direction, the disc will be closed by fluid pressure and dead weight so as to cut off the flow.

Maintenance

1. For DIN butt welded check valves that are not to install temporarily, they should be stored in dry and ventilated room, side flange of the flanged valve must be sealed.

2. The valve for long-term storage should be checked regularly. The surface of the valve must be clear of dirt and coated with anti-rust oil.

3. The following conditions of DIN lift type welded check valve should be inspected regularly after installation:

1) Wear pattern of sealing surface

2) Wear pattern of rotary rocker

3) Dirt accumulation between the inner chamber of the valve body and sealing surface

4. Sealing performance test should be implemented after every time maintenance and assembly of DIN butt welded check valve.

TallKee Valve Industry is a professional manufacturer lift check valves in China. Our main products cover ball valves, gate valves, globe valves, check valves (non return valves) and strainers. Our valves have passed DIN and API certifications. Our DIN lift type butt welded check valves are widely applied in tap water, sewage, construction, petroleum, chemical, food, medicine, textile, electric power, shipbuilding, metallurgy, and other pipeline systems.

Related Product

- API Swing Type Welded Check ValveAPI welded swing check valve (swing reflux valve) is an automatic valve that is installed on one-way flow pipelines. It can be widely applied in tap water, sewage, construction, petroleum, chemical, food, medicine, textile, electric power, shipbuilding, metallurgy, and other pipeline systems. This API swing check valve is mainly made up of valve body, disc...